Flat Gauge Glass

FL-xxx

These glasses are designed for use in armored-type liquid level gauges. They are manufactured of borosilicate glass under carefully controlled conditions to provide a high strength tempered glass with the greatest degree of visibility. These glasses are available in sizes 1-9. The three basic types of gauge glass are noted below:

Type A, Plain is designed for moderate pressure steam boilers and for liquid level indicators.

Type A, High Pressure will take non-steam pressure up to 5000 psi.

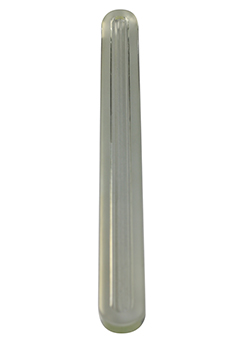

Type B, Reflex is made for extra ease in locating liquid levels. This gauge glass has vertical prisms extending the full viewing length of the glass. The prism side faces the liquid. The sections off the prisms not covered with liquid reflect light brilliantly, thus the liquid level stands out extra clearly from a great distance away.

| Type A Plain |

Type B, Reflex |

Mica Shield |

|

|

|

Corrosives:

The borosilicate glass used to manufacture these products is outstanding for chemical services. Certain limitations, however must be recognized.

Some materials reduce the useful life of the gauge glass by chemical action, eg: hydrofluoric acid (HF): hot concentrated phosphoric acid; sodium and potassium hydroxides above 125° F; steam or superheated water above 250° F. Except for HF, protection from reagents such as these may be supplied by using a mica shield to cover the glass.

Reflex glasses cannot be shielded.

Note: When these protective coverings wear out the entire assembly should be replaced.

Alkaline solutions attack glass very slowly at room temperature, but as temperature is increased to over 100° F the corrosive rate rises rapidly.

Gaskets in non-asbestos and grafoil are available for these glasses.